Understanding the Critical Role of the Crankshaft on Engine: A Deep Dive into Diesel Engine Parts & Spare Parts Suppliers

Introduction to Crankshaft in Diesel Engines

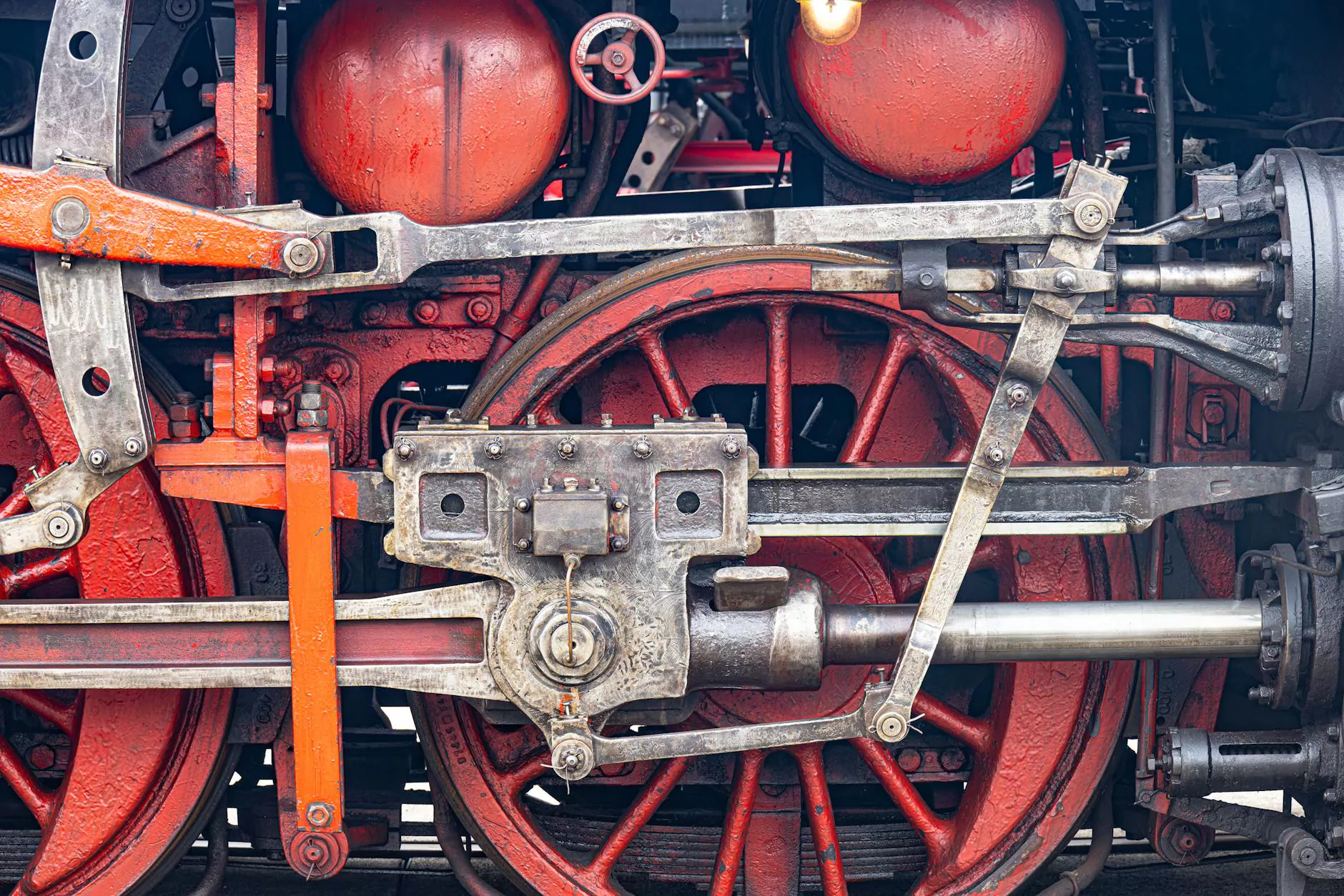

A crankshaft on engine is one of the most vital components within internal combustion engines, especially in diesel applications where robust and durable parts are essential for high performance and longevity. As the central rotating component, the crankshaft converts the linear motion of the pistons into rotational force, enabling the vehicle or machinery to operate efficiently. Its design, materials, and manufacturing precision directly impact engine power delivery, fuel efficiency, and durability.

The Role of the Crankshaft on Engine in Modern Diesel Technology

In modern diesel engines, the crankshaft on engine serves multiple core functions beyond simply transmitting power. It acts as a key component coordinating the timing of combustion events, controlling vibration levels, and supporting the overall mechanical integrity of the engine in demanding operating conditions. Diesel engines, known for their high compression ratios and torque output, particularly rely on the crankshaft's strength and resilience.

Materials and Manufacturing of Crankshafts for Diesel Engines

To withstand the intense stresses and thermal loads typical of diesel applications, crankshafts are manufactured from high-strength materials, including forged steel alloys like chromoly steel or nodular cast iron. Advanced manufacturing processes such as forging, machining, and heat treatment ensure optimal grain structure, toughness, and fatigue resistance. Precision balancing is also critical to minimize vibrations and extend the lifespan of the part.

Design Variations of Crankshafts in Diesel Engines

- Single-throw crankshafts: Common in smaller engines, simple design for basic torque transfer.

- Multi-throw crankshafts: Found in larger, multi-cylinder engines, allowing smoother operation and better power distribution.

- Forged vs. Cast crankshafts: Forged crankshafts are stronger and more durable, suitable for high-performance and heavy-duty engines.

- Ill-Fitting and counterweight designs: Designed to optimize balance, reduce vibrations, and improve overall engine stability.

The Importance of Quality Spare Parts in Maintaining the Crankshaft on Engine

Using high-quality spare parts from reputable spare parts suppliers ensures the longevity and performance of your diesel engine's crankshaft on engine. Replacement components must meet strict OEM specifications to withstand engine stresses and maintain optimal engine timing and efficiency.

Common Issues with Crankshafts and How Premium Parts Solve Them

While crankshafts are designed to last, several issues can occur over time, including:

- Crankshaft cracks or fractures: Often due to fatigue from constant stress.

- Bearing failure or wear: Can lead to abnormal vibrations and damage.

- Wobbling or misalignment: Caused by poor balancing or manufacturing defects.

High-quality spare parts from trusted suppliers like client-diesel.com are essential to prevent these issues. They provide precision-engineered crankshafts, bearings, and related components that meet or exceed OEM standards, ensuring reliable engine operation.

Choosing the Right Diesel Engine Parts and Spare Parts Suppliers

Factors to Consider:

- Material Quality: Ensure components are made of durable, high-grade materials.

- Manufacturing Precision: Look for suppliers with strict QC processes.

- Compatibility: Verify that parts fit perfectly with your specific engine model.

- Certifications: Check for ISO or industry-specific certifications guaranteeing quality standards.

- Reputation and Reviews: Choose suppliers with positive customer feedback and proven track records.

Benefits of Partnering with Reliable Spare Parts Suppliers like client-diesel.com

Partnering with trusted suppliers such as client-diesel.com offers several advantages:

- Access to premium diesel engine parts: Including high-grade crankshafts, pistons, bearings, and more.

- Competitive pricing: Due to large-scale procurement and efficient logistics.

- Technical support: Expert guidance to select the best components for your engine.

- Fast delivery: Ensuring minimal downtime for maintenance or repairs.

- Warranty services: Guaranteeing quality and service assurance.

Replacing and Maintaining the Crankshaft on Engine

Proper maintenance of the crankshaft on engine involves regular inspections for cracks, wear, and alignment. When signs of damage appear, timely replacement with OEM or high-quality aftermarket parts is crucial. The process typically involves:

- Removing the damaged crankshaft carefully to avoid damaging surrounding components.

- Inspecting crankshaft bearings, journals, and related parts for wear.

- Installing a matched, high-quality crankshaft that meets industry standards.

- Balancing and aligning the assembly.

- Performing comprehensive testing before returning to service.

Innovations and Future Trends in Crankshaft Technology

The industry is continually advancing towards more resilient and lightweight crankshaft designs. Innovations include:

- Carbon fiber reinforced materials: For improved strength-to-weight ratio.

- Computer-aided design (CAD) simulations: Allowing optimized crankshaft dynamics and balancing.

- Integrated crankshaft and camshaft systems: For simplified engine architecture.

- Enhanced lubrication techniques: To reduce wear and increase lifespan.

These advances aim to improve diesel engine performance, fuel efficiency, and environmental compliance, while also extending component life cycles.

Why Choosing the Right Spare Parts Suppliers Matters for Your Business

If your business relies on diesel engines, whether for transportation, construction, or industrial applications, the quality of your spare parts directly affects productivity and operational costs. Partnering with proven suppliers ensures:

- Reduced downtime: Reliable parts mean fewer repairs and longer intervals between replacements.

- Enhanced engine performance: Top-tier parts optimize power output and efficiency.

- Cost savings: High-quality durable parts reduce the frequency and costs of repairs.

- Regulatory compliance: Meeting emissions standards and safety regulations.

Conclusion: The Critical Impact of the Crankshaft on Engine in Diesel Engine Performance

The crankshaft on engine is undeniably a cornerstone of diesel engine design and functionality. Its quality, design, and maintenance directly influence engine performance, efficiency, and durability. By choosing premium parts from trusted spare parts suppliers like client-diesel.com, customers can ensure their engines operate smoothly, meet demanding work schedules, and achieve maximum lifespan.

Whether you are an OEM manufacturer, a repair shop, or a fleet operator, investing in high-quality crankshafts and related components is essential for success. Emphasizing proper maintenance, sourcing from reputable suppliers, and understanding the intricacies of crankshaft technology will empower you to optimize engine performance, reduce costs, and sustain your business growth.

Explore More About Diesel Engine Parts and Spare Parts Solutions

Visit client-diesel.com for comprehensive product ranges, expert advice, and industry-leading spare parts solutions tailored for diesel engines worldwide.